Harken is synonymous throughout the yachting world with top-quality sailboat deck hardware. This renowned company, founded in 1967 on the basis of a brilliant invention by Chairman Peter Harken (the first Harken ball bearing block), can now provide all sailboat deck hardware, including winches, needed for America’s Cup races.

Cleaning of most of the mechanical components used in Harken winches is done by the SONICA 45L EP S3 ultrasonic cleaner,

with Sweep System technology produced by SOLTEC Srl of Milan.

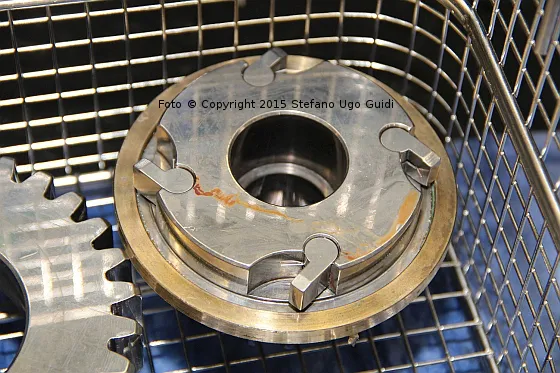

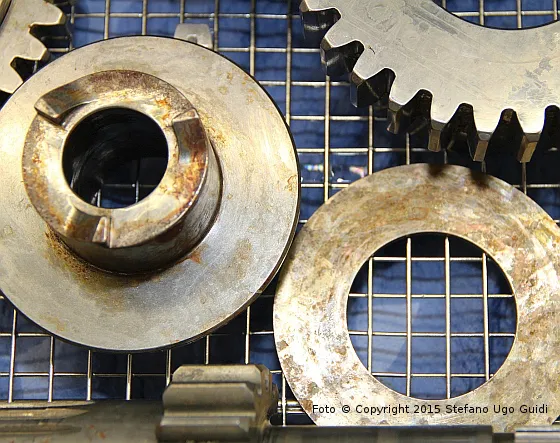

Fig. 1

Figura 1/2/4 - Details with obvious signs of dirt and oxidation before ultrasonic treatment

Figura 3 - Winch parts before ultrasonic treatment

During previous editions of the America’s Cup, first in 2003 with One World Challenge and thereafter in 2007 with the Desafio Español 2007 team, SOLTEC acquired a wide range of in-depth technical skills and developed perfect ultrasonic precision cleaning

products, for more than 2000 different mechanical and hydraulic parts. The parts, made from technologically advanced materials, such as Delrin, Ertalite, Torlon Peak, stainless steels such as 316L, 17-4ph, 13/8 and 2205, aluminum alloys 5083, 6061 and 7000, titanium, carbon fibre and composite epoxy laminates were treated with ultrasound, with incredibly outstanding results.

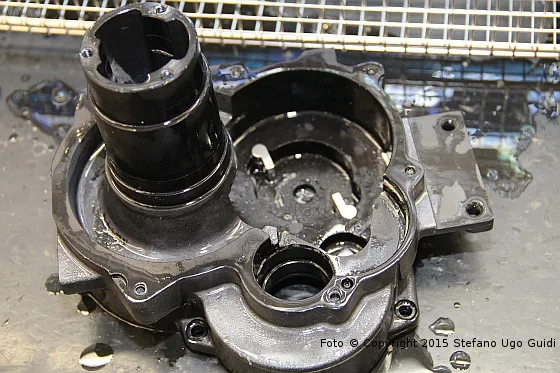

Fig. 5

Detail with obvious signs of dirt and oxidation before ultrasonic treatment

Fig. 6

Detail after ultrasonic treatment

Fig. 7

Fig. 8

Fig. 7/8 Detail before and after ultrasonic treatment

But let’s look in detail at how the SONICA ultrasonic cleaning system works.

During an America’s Cup race, the winches have to be in perfect working order, otherwise a mixture of nautical grease, salt, oxidation residues and wear particles can even cause the whole system to seize up.

To prevent this, the whole winch is completely dismantled into its component parts, and each piece is placed in an ultrasonic cleaning bath in a special basket and undergoes an ultrasonic cleaning process that lasts for an average of 30 minutes.

The ultrasonic cavitation process generated inside a special alkaline washing liquid specifically designed for this SONICA ML application produces micro-cavitation bubbles, which have enough energy to detach all dirt particles from parts being cleaned.

After ultrasonic cleaning, the pieces treated are then reassembled, thus making the part as good as new, and ready for the next race.

Fig. 9

Various details after SONICA ultrasonic cleaningwith SONICA ML concentrated alkaline detergent

Fig. 10

Fig. 11

Figure 10/11 - Detail after SONICA ultrasonic cleaning. Even in spring mechanisms there are no grease or dirt residues. The part is ready to be reassembled

after maintenance.

Thanks to the experience and advice of Massimiliano Zafaro, Harken Italy Assembly Supervisor, the Italian branch of the Group where Harken winches are designed and produced for the whole world, we have been able to test and re-test the effectiveness

of our SONICA ultrasonic cleaning system, which has been successfully applied, not only in recent editions of the America’s Cup, but also in countless repairs of mechanical winch components which come to servicing centre to be restored to their

original factory condition.

Stefano Guidi

Managing Director

SOLTEC Srl

To get the complete technical document | Ultrasonic precision cleaning of yacht winch components |