Cleaning and maintenance of fire arms

Submitted by soltec-admin on Mon, 04/26/2010 - 10:19

A practical and precise example of maintenance of a Smith & Wesson Magnum 44.

Last month, at BIGNAMI's S.p.a. Company located in Ora (BZ) Italy, which specializes in the distribution and sale of hunting arms, sport's shooting, personal defence, security and protection, I wanted to personally test, the efficency of ultrasonic cleaning to remove the carbon residues due to the explosion of gunpowder within the cartriges at their service laboratory.

In the specific case, with the help of one their specialized technicians, a Smith & Wesson Magnum 44 revolver was completely disassembled which had some working problems.

Initially the revolver was completely disassembled

The cylinder showed remarkable residues of mixed gunpowder combustion. The picture shows how the Magnum 44 cylinder is heavily coloured in dark grey.

The revolver's single components were positioned inside the basket of SONICA® ultrasonic cleaner, which previously had been filled with a special SONICA® ML detergent that showes excellent detergent characteristics for the removal of the residues generated by the gunpowder explosion from the stainless steel parts. The Magnum 44 revolver was immersed in the ultrasonic cleaning liquid for about 20 minutes at a temperature of 46°C. using the Sweep System Technology (modulated ultrasonic frequency system).

As you can see, after only 20 minutes of ultrasonic cleaning, any carbon residue was completely removed from every single component.

After the ultrasonic cleaning a brief rinsing was used with tap water in order to remove all traces of SONICA® ML detergent. One of the frequent problems that we find after the ultrasonic cleaning and rinsing with water based detergents is the complete removal of water from the mechanical pieces. The problem has been resolved by a means of a SONICA® Dewatering tank with it's own DWG-1 Product. The dismantled handgun was immersed in the special Dewatering Tank for few seconds. In order to completely remove the water from every single pieces takes just 15 seconds. The same technology was used to dry the winch sofisticated components of sailing boats at Desafio Español base in Valencia during the last America's Cup.

As you can see the handgun is not only cleaned and perfectly dried, but also lubrificated thanks to the anti-oxidative and protective characteristics of the SONICA® DWG-1 product.

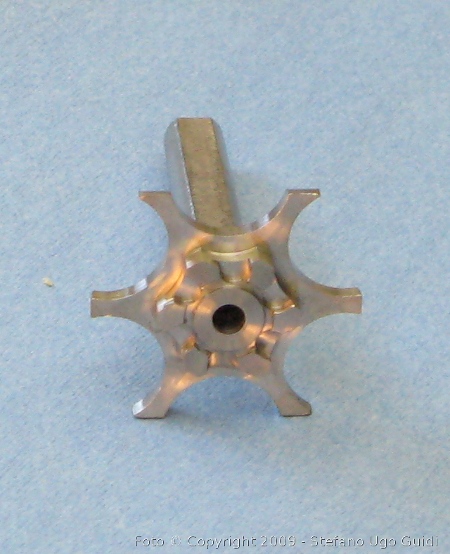

Particular of the row cylinder mechanism after the ultrasonic cleaning, rinsing, drying and the lubrification process

Cylinder characteristics before ultrasonic cleaning

Cylinder characteristics after cleaning

Photo of Magnum 44 Smith & Wesson after ultrasonic cleaning process

The handgun is ready for the final assembling phase

Beautiful cylinder characteristics after ultrasonic cleaning operation

For more information please contact us to the following address:

SOLTEC® Srl Via Castelbarco, 17 - 20136 Milano (MI) Italy

tel. +39 0258308378 Fax: +39 0258308595

Mr. Stefano Guidi